Subtotal: 26,00 €

• Produces light, thixotropic

fillers • For epoxy, polyester and polyurethane resins Area of

application:

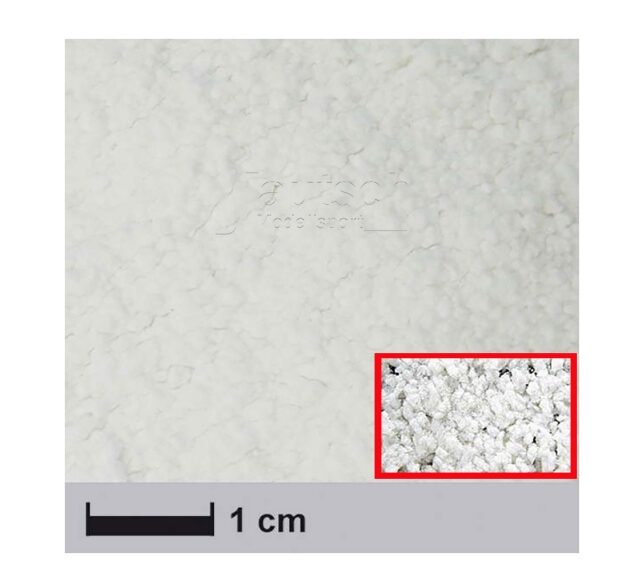

Production of light, non-sagging adhesives and free-flowing molding compounds as well as coupling layers in mold construction, using a mixture of 50% by volume glass fiber flakes and 50% by volume cotton flakes . Cotton flakes increase the dimensional stability as well as the impact and abrasion resistance of the molded materials. Very well suited for epoxy, polyester and polyurethane resins and rubber compounds. Good chemical resistance (including alkalis). Very inexpensive, low weight. 5 liters of cotton flakes = 1 kg

Appearance:white flakes, fiber length: ca. 350 µm (typically 150-500 µm), fiber diameter: 10-25 µm (1-3 denier), specific gravity: 1.5 g/cm³, chars at 120 °C, decomposes at 150 °C, tensile strength up to approx. 800 N/mm²

Insoluble in acetone, dimethylformamide or 40% NaOH, water absorption approx. 0.3 g per g cotton tufts.

The volume specification serves to give a better idea of the delivery quantity. This is the loose bulk quantity. During transport and storage, the contents of the container can compact.

Content: 50g = (approx. 350ml)

Super-Gold Cyanoacrylate Thin Foam Safe Odorless 28g (1 oz)

Super-Gold Cyanoacrylate Thin Foam Safe Odorless 28g (1 oz)

Reviews

There are no reviews yet.